Pearl White Polypropylene (PP) is a versatile plastic known for its unique aesthetic appeal and functional properties. Characterized by its shimmering, pearl-like finish, this material combines elegance with practicality, making it a popular choice across various industries.

Properties of Pearl White PP

Aesthetic Appeal: The most notable feature of Pearl White PP is its striking appearance. The pearlescent finish gives it a luxurious look, making it ideal for consumer products that require visual appeal, such as packaging, household items, and cosmetics.

Durability: Pearl White PP exhibits excellent chemical resistance, making it suitable for various applications where exposure to harsh substances is a concern. Its robust structure ensures longevity, reducing the need for frequent replacements.

Lightweight: Like traditional polypropylene, Pearl White PP is lightweight, which is advantageous in industries where weight reduction is critical, such as automotive and packaging. This characteristic contributes to lower shipping costs and ease of handling.

Thermal Stability: Pearl White PP can withstand moderate temperatures, which allows it to be used in applications involving heat. Its thermal stability makes it suitable for items that may be exposed to varying environmental conditions.

Recyclability: An essential feature of Pearl White PP is its recyclability. It can be processed and repurposed, making it an environmentally friendly option compared to other materials. This aligns with the growing demand for sustainable materials in product development.

Manufacturing Process

The production of Pearl White PP typically involves the addition of pearlescent pigments during the polymerization process. These pigments create the characteristic shimmer by reflecting light differently than standard PP. The manufacturing process includes:

Polymerization: Polypropylene is synthesized through polymerization of propylene monomers, often using catalysts to initiate the reaction.

Incorporation of Pigments: During the compounding stage, pearlescent pigments are blended into the polypropylene matrix. This step is crucial for achieving the desired aesthetic effect.

Forming and Molding: The compounded material is then extruded or injection-molded into various shapes and products. This versatility allows manufacturers to create everything from packaging materials to consumer goods.

Applications of Pearl White PP

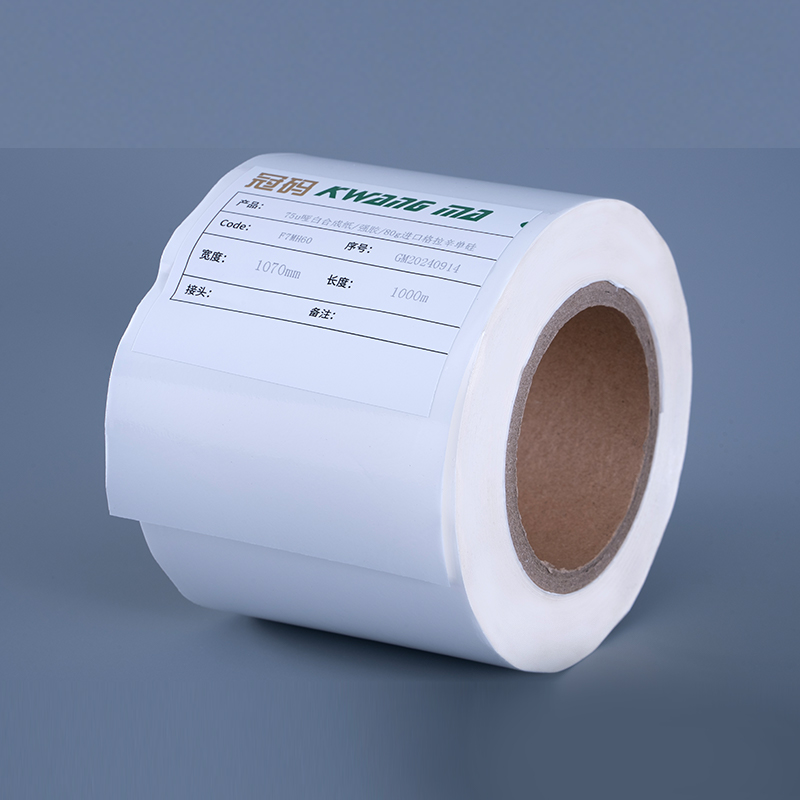

Packaging: The beauty of Pearl White PP makes it a preferred choice for luxury packaging. It is widely used in cosmetic containers, food packaging, and gift boxes, where aesthetics play a significant role.

Automotive Components: In the automotive industry, Pearl White PP is utilized for interior trim, dashboards, and exterior panels. Its lightweight and durable nature helps improve fuel efficiency without compromising style.

Consumer Products: Household items such as storage bins, kitchenware, and decorative products often feature Pearl White PP due to its appealing look and durability.

Electronics: In the electronics sector, Pearl White PP is used for casings and housings, where a sleek design is crucial for market competitiveness.

We have a professional R&D team and strong manufacturing capabilities to ensure product quality and delivery while doing a good job in product iteration and innovation.

Address : Building 2. No.111 Xincheng Road, Xitangqiao Street, Haiyan, Jiaxing, Zhejiang Province, China

Phone: +86-150 0573 0249

Tel: + 86-0573-8685 2732

Fax: + 86-0573-8685 2732

E-mail: [email protected]

Copyright© Zhejiang Guanma Packaging Co., Ltd.

Privacy

Privacy

OEM Self Adhesive Label Material Manufacturers Waterproof Labels Suppliers Custom Adhesive Label Material Factory

English

English русский

русский Español

Español عربى

عربى