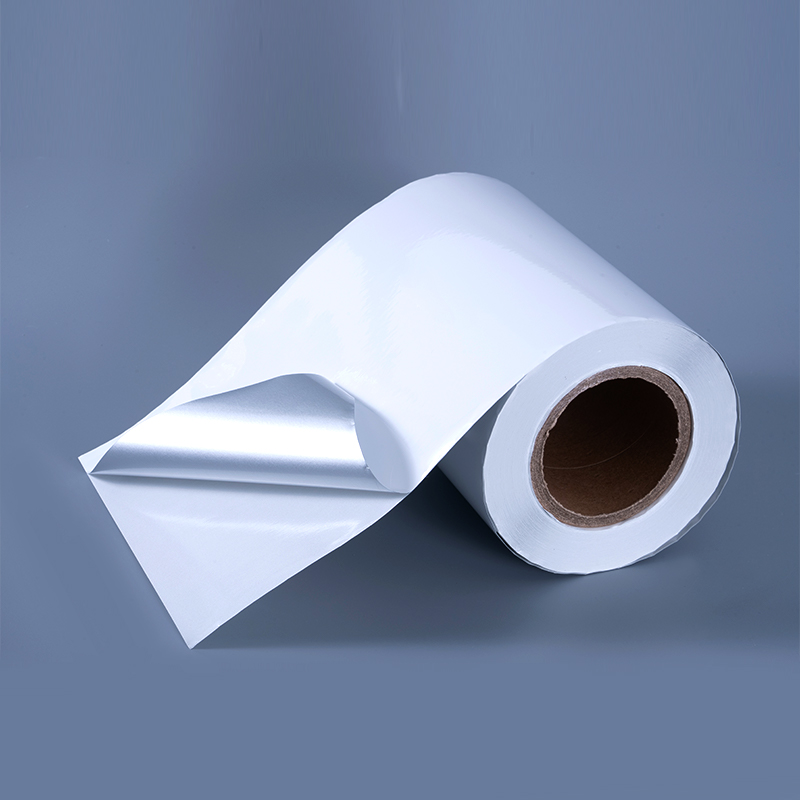

Manufacturing process of aluminum foil PET film

The manufacturing process of aluminum foil PET film includes several key steps, mainly covering the production of PET film, evaporation of aluminum layer and post-processing.

Production of PET base film

The first step of aluminum foil PET film is to produce high-quality PET base film. Polyester film is manufactured by melt extrusion and stretching process. This process determines the transparency, mechanical properties and thermal stability of the film, so it requires strict quality control of raw materials, and the temperature and stretching rate must be precisely controlled during the production process.

Aluminum layer evaporation

The aluminum layer is evaporated onto the surface of PET film by physical vapor deposition (PVD) technology. During the aluminum evaporation process, aluminum metal evaporates into gas at high temperature and then condenses on the surface of PET base film to form a uniform metal film. The thickness, uniformity and adhesion of the aluminum layer have a direct impact on the performance of the final product.

Post-processing

After the aluminum layer is evaporated, the aluminum foil PET film will undergo various post-processing, such as coating, cutting, stretching and other treatments. These steps can further enhance the functionality of the film, such as increasing its UV resistance, abrasion resistance or improving its printing performance. For some applications, the aluminum foil PET film may also need to be printed to enhance its appearance and brand recognition.

Technical Challenges of Aluminum Foil PET Film

Although aluminum foil PET film has excellent performance in many fields, it also faces several technical challenges in its manufacturing process:

Uniformity Control of Aluminum Layer

One of the key characteristics of aluminum foil PET film is the uniformity of its surface aluminum layer. Uneven thickness of the aluminum layer may lead to unstable film performance, especially in the fields of electronics and food packaging, the uniformity of the aluminum layer directly affects the protective effect and product quality. Therefore, during the evaporation process, the temperature, evaporation rate and operating environment of the equipment need to be precisely controlled to ensure uniform coverage of the aluminum layer.

Adhesion Issues

The adhesion between the aluminum layer and the PET base film is a key factor affecting the quality of aluminum foil PET film. Insufficient adhesion between the aluminum layer and the PET base film may cause the aluminum layer to fall off or peel off, especially when the film is stretched or in a high temperature environment. Therefore, in the production process, to ensure good adhesion between the aluminum layer and the base film, this can be solved by surface treatment, adding adhesives, etc.

We have a professional R&D team and strong manufacturing capabilities to ensure product quality and delivery while doing a good job in product iteration and innovation.

Address : Building 2. No.111 Xincheng Road, Xitangqiao Street, Haiyan, Jiaxing, Zhejiang Province, China

Phone: +86-150 0573 0249

Tel: + 86-0573-8685 2732

Fax: + 86-0573-8685 2732

E-mail: [email protected]

Copyright© Zhejiang Guanma Packaging Co., Ltd.

Privacy

Privacy

OEM Self Adhesive Label Material Manufacturers Waterproof Labels Suppliers Custom Adhesive Label Material Factory

English

English русский

русский Español

Español عربى

عربى